L7: Inventory is your friend. Here is why.

Fluctuations cause problems for all production systems.

During the shift, we produce different products or product variances. Processes will take longer than planned or will be faster. We can have different quality issues or breakdowns. Parts may arrive early or late. Essentially, the material does not flow at a consistent speed but often moves in waves - sometimes faster and sometimes slower. Fluctuations create disturbances in the production process therefore a major part of lean manufacturing is reducing fluctuations.

To eliminate the impact of fluctuations - inventory is our friend.

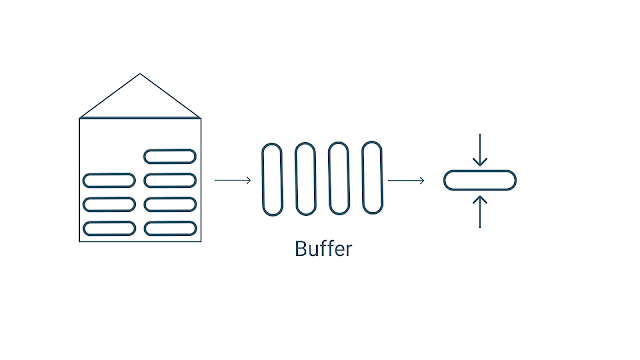

The buffer inventory goes up and down like waves and decouples the fluctuations. This allows our machines and operators to work at a constant speed. Consequently, we can provide our internal customers with material despite e.g., a fluctuating demand.

If we cut our inventory,

our ability to decouple these fluctuations decreases.

Inventory is one of the 7 wastes in production that we should reduce or even eliminate. If we, however, reduce our inventory too much, we can stop production, and our efficiency goes down. We create more work for internal logistics and create even more fluctuation. Without buffers, each random fluctuation would influence the entire system. At any given time, the slowest process at that time would define the speed of the line.

This can soon be more expensive than

the buffer inventory in the first place.

Inventory helps us decouple fluctuations, making our production system more synchronized and robust.

The larger is our buffer inventory, the more fluctuations we can buffer. The more fluctuations we can buffer the higher is our utilization and our output. On the other hand, the larger the buffer, the longer is the lead time and the higher is the inventory and our expenses. The larger the buffer the more fluctuations it buffers and less we know what is happening.

Having too much inventory has many negative side effects.

The excess of inventory provokes hidden and not-so-hidden costs. Besides the apparent tied-up capital, there is storage, handling, taxes, insurance, administration, obsolescence, and theft - to name only the most significant effects on the inventory costs. To learn more, check the allaboutlean blog.

Overall, the buffer size is a trade-off between utilization and

throughput on one hand and the lead time and inventory cost on the other

hand.

In lean manufacturing, the tendency is clearly toward smaller buffers.

While most companies understand that lean production involves a reduction of inventory, they often miss the point that the system has to be improved too. The LEAN-enthusiastic companies that focus only on reducing inventory can get to the point of having little inventory. This decreases performance - they should increase their inventory, which might sound odd.

Having the right inventory level is essential for the company's success.

The answer to how to stay at or near a good level of inventory is Pull - let's talk about it later ;)

This learning comes from the book: All About Pull Production by Christoph Roser. The book is a breakthrough in my LEAN understanding. It is a must-read for all Lean practitioners.

Cheers,

Marek

Comments

Post a Comment